With feedback control, we produce high-precision VOAs that lock the set attenuation value regardless of environmental variations. All types VOAs can be made in this way.

High Precision/Repeatability Variable Attenuators (VOAs)

(0.1dB accuracy 1-40dB, 0.6dB accuracy 40-65dB, temperature insensitive)

$495+

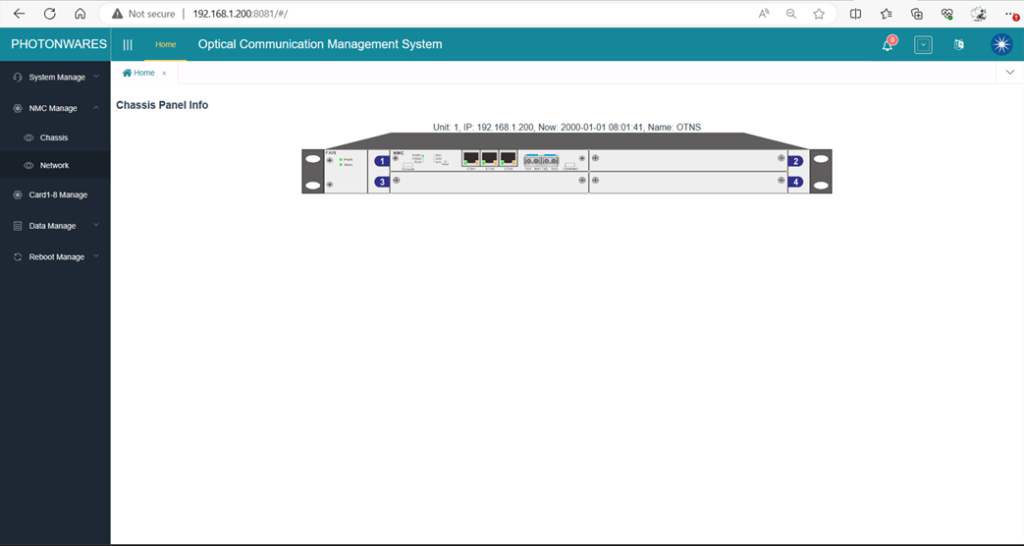

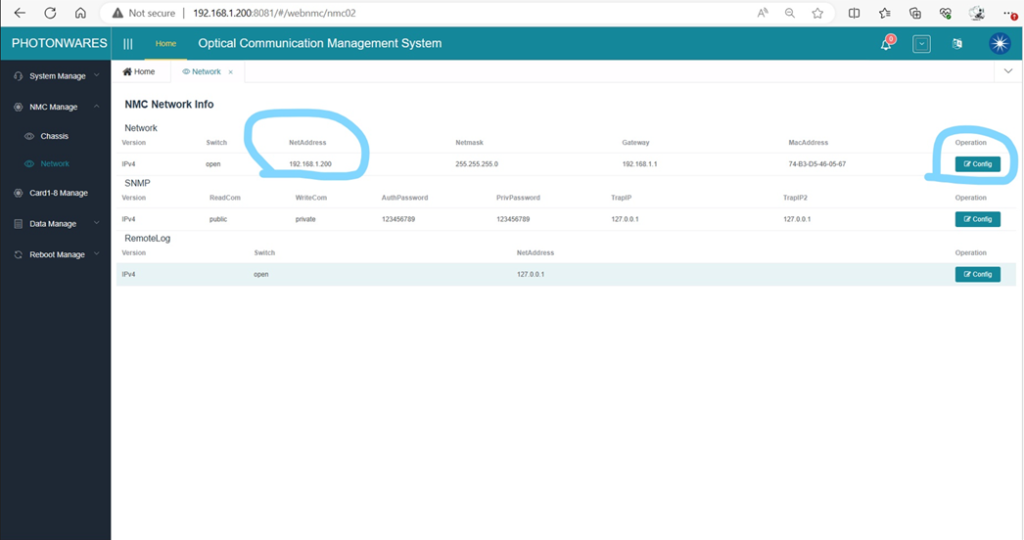

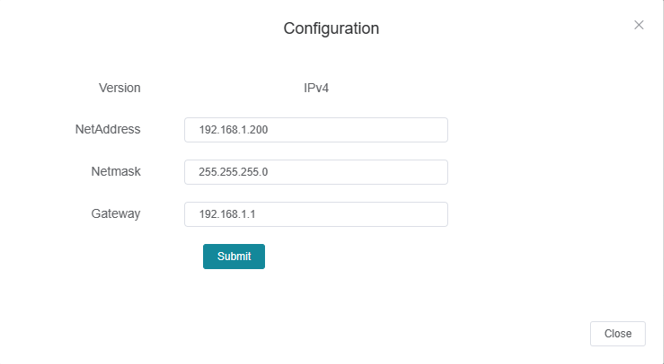

Programmable VOA Array System

(Ethernet/SNMP, 350nm to 2600 nm, 0.2dB Loss, 60dB Attenuation, All fiber types, Up to 198 channels)

$2574+

We uniquely produce MEMS VOA and Fiber-Fiber VOAs that can reach 80dB light blocking level for applications requiring large attenuations.

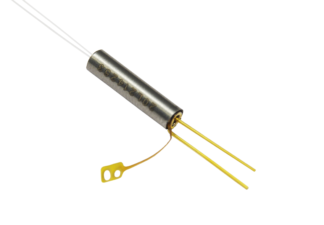

MEMS Straight Fiber Optical Variable Attenuator

(1060 to 2300nm, 0.7dB loss, SM, PM, MM)

$97 – $135

If your operation requires VOA with optical loss as small as possible, our Fiber-Fiber VOA is nearly lossless. 0.005 dB insertion loss version is available for purchase.

Ultra-Broadband Variable Attenuators – Fiber-Fiber™

(300-2600nm, all fiber types with core 3mm to 1mm, ultra-low loss 0.2dB)

$123+

We lead the market in high-speed VOAs. Compact integrated modules that take out optical power spikes or regulate the optical power are available.

High Speed Variable Fiber Optical Attenuators (VOAs) – NanoSpeed™

(fast: 200ns, 400-2400nm, vibration insensitive, low loss)

$750+

For high optical power applications, we uniquely produce High Power VOA up to 20 W.

High Speed Variable Fiber Optical Attenuator – NanoSpeed™

(960nm-2200nm, 100kHz, 20db, Bidirectional, SMF, PMF, High Power)

$750 – $1,450

For high optical power applications, we uniquely produce High Power VOA up to 20 W.

Large Core Fiber Variable Optical Attenuator Motor – Fiber-Fiber™

$1120+

We produce the smallest VOA on the market, with a diameter of only 3.2 mm. This family of MEMS VOAs can also operate under a shock/vibration environment.

MEMS Ultra Mini Variable Optical Attenuator

(vibration insensitive, fastest/smallest MEMS VOA on the market)

We produce VOA arrays up to 24 channels.

Mini MEMS 8 Channel Variable Optical Attenuator Array

(ultra-compact)

We produce the most comprehensive choice for manual VOAs

Manual Variable Fiber Optical Attenuators

(ultra-broadband 350-2600nm, ultra-low loss 0.3dB, all fiber types: SM, PM, large mode)

$59+

Perfected over 20 years, we offer the lowest loss, the highest attenuation, the fastest, the smallest, and the most reliable fiber attenuators in the industry. Our thermal actuation MEMS VOAs have the smallest size, the highest attenuation level, and ultra-high reliability. Our Fiber-Fiber™ MEMS series VOAs offer unique performances of near-lossless, ultra-broadband, and all-type fiber compatibility. Our high-precision VOAs have a built-in position sensor achieving high stability/repeatability as well as linearity. For high-speed operation, our solid-state NanoSpeed™ VOAs set an industry-standard in low loss and fast rise/fall, as well as high power handling. The table below guides fiber VOA selection according to your key requirement. All VOAs can be delivered in a turn-key net-ready box. Moreover, we provide custom solutions with in-house micro-assembly and MEMS wafer fabrication.