Fiber Couplers/Splitters

We offer a full line of fiber optic couplers and splitters supporting SM, MM, PM, large core, and double-clad fibers across 300–2000 nm, with power handling up to 100 W and operating temperatures up to 300°C. Three fabrication methods are employed: fusion, micro-optics, and planar lightwave circuit (PLC), each optimized for specific performance and cost requirements.

- Fusion couplers, made by melting a section of twisted fibers, offer the lowest insertion loss (~0.3 dB) and highest power handling, with a limited wavelength bandwidth of ±40 nm and polarization extinction ratio below 23 dB.

- Micro-optic couplers, built by coupling two lensed fiber collimators with an optical element in between, provide ultra-broad bandwidth (±200 nm), high polarization extinction ratio (>30 dB), excellent thermal stability, and allow integration of filters and polarizers, albeit at higher cost.

- PLC couplers, fabricated through photolithography and etching, are ideal for high fiber counts, offering compact size, broad bandwidth (±200 nm), and low cost, though with higher coupling loss and lower power handling due to epoxy-based light paths. PLCs typically feature fixed, uniform splitting ratios, with custom ratios achievable at significantly higher setup costs.

Note: while fiber couplers efficiently split light into multiple outputs, they are not suitable for combining multiple beams due to the inherent 50% loss per combining stage; for low-loss beam combining, refer to our fiber combiners utilizing wavelength, polarization, or beam size differences.

-

SM Fiber Couplers/Splitters

$85+

-

PM Fiber Couplers/Splitters

$250+

-

MM Large Core Fiber Couplers

$173+

-

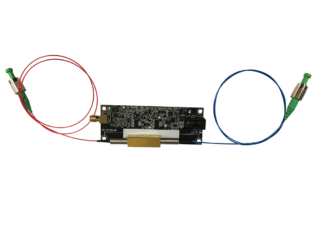

Variable Fiber Optical Splitters

Electrically Variable Coupler Ratio, High Speed, All Wavelengths, SM, PM, MM

$980+ -

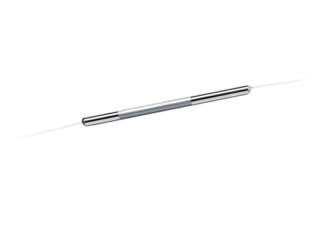

Wavelength Based Fused Fiber Combiners/Splitters (WDM)

Combine/Split Beams of Different Wavelengths

$25+ -

Polarization Based Fiber Combiner/Splitter

SKU: PBCS

$445+

-

Fiber Core Size Based Fiber Combiners

Combine/Split Beams of Different Polarization or Core Size

$325+