SKU: FEND

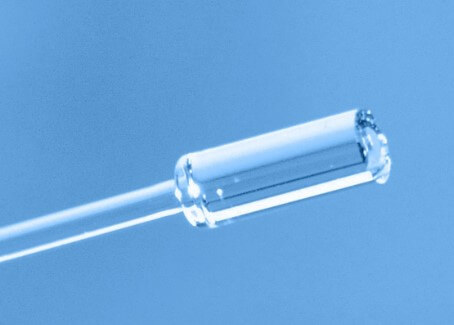

The end-capped fiber increases its power handling by reducing the laser power density to a level below the damage threshold through modification at the fiber end. Agiltron has developed a manufacturable fiber fusion process to integrate a coreless end-cap to the end face of optical fibers and a precisely controlled fiber polishing process to control the end cap length and surface quality. This end cap technology, which expands the laser beam inside the fiber, is designed for output termination of high power fiber lasers and fiber amplifiers, but it also involves a pigtail process to produce high power fiber collimators.

Reviews

There are no reviews yet.